Technology

Ever since its founding, easy2cool GmbH has set out to revolutionise the market for mobile cooling. To this end, the company has developed a novel, sustainable thermal insulation material in cooperation with the Institute of Natural Materials Technology at the TU Dresden. The goal was to find an environmentally friendly insulation material that could serve as a sustainable alternative to expanded polystyrene (EPS).

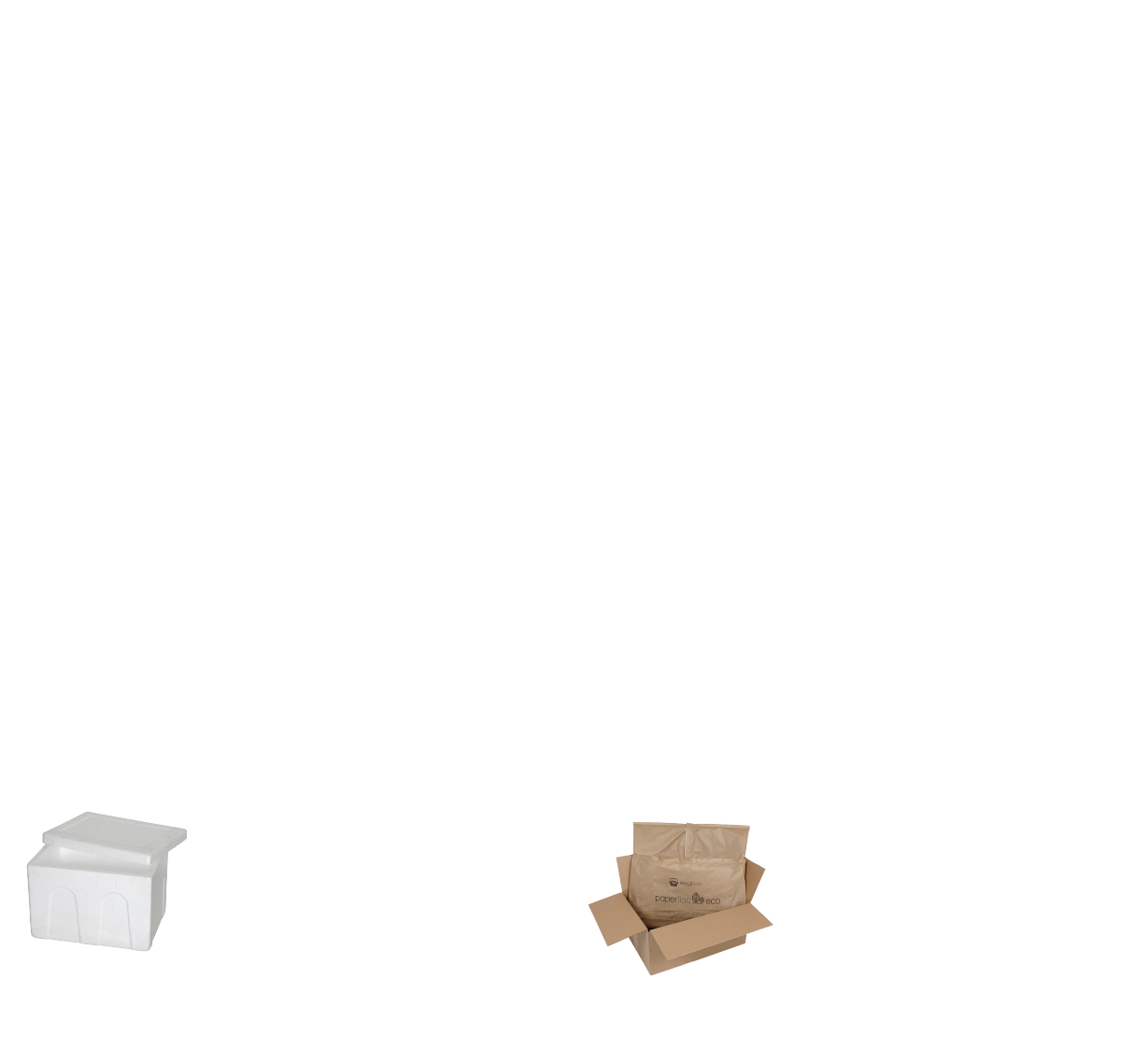

The solution: paperfloc – a new type of ecological shipping insulation made from cellulose fibers. For this purpose, waste paper is shredded in a special process and finally processed into insulating mats or bags.

Meanwhile, the range of innovative products extends from cool boxes and gel packs for the leisure sector to solutions for professional deep-freeze transport. The in-house production facility in Bavaria ensures a high degree of flexibility and is the enabler for the high-quality standards

paperfloc Technology

Sustainability and resource efficiency play an essential role, from production to disposal of our paperfloc shipping insulations.

Moreover, our system keeps the disposal effort for the consumer as low as possible.

paperfloc Performance

The paperfloc system offers the best price/performance ratio compared to insulation systems currently on the market for shipping temperature-sensitive products. Our paperfloc packaging has been tested in over 1,000 internal and external climate chamber and shipping tests.

In our development department, our shipping packaging is optimized for your purpose. The validation of all packaging according to DIN 10543 takes place in our in-house laboratory.

paperfloc Impact

In order to produce the sustainable insulation material paperfloc, waste paper is shredded in a special process and finally processed into insulating liner or pouches. For this purpose, cutting waste from regional cardboard production is used in order to keep the CO2 footprint as low as possible.The production of paperfloc requires significantly less energy and emits 95% less CO2 than comparable packaging made of EPS.

paperfloc Recyclability

Our proven paperfloc technology ensures that food stays well refrigerated during shipping. In this context, we rely on recycled waste paper as a sustainable alternative to conventional insulation such as Styrofoam. An independent study by the Graz University of Technology shows that fibers that comprise cardboard can be recycled more than 25 times. In the production of paperfloc, we use waste from cardboard production and can therefore upcycle the material. After using our paperfloc insulation, the customer can simply put it in the paper waste and paperfloc is 100% recycled.

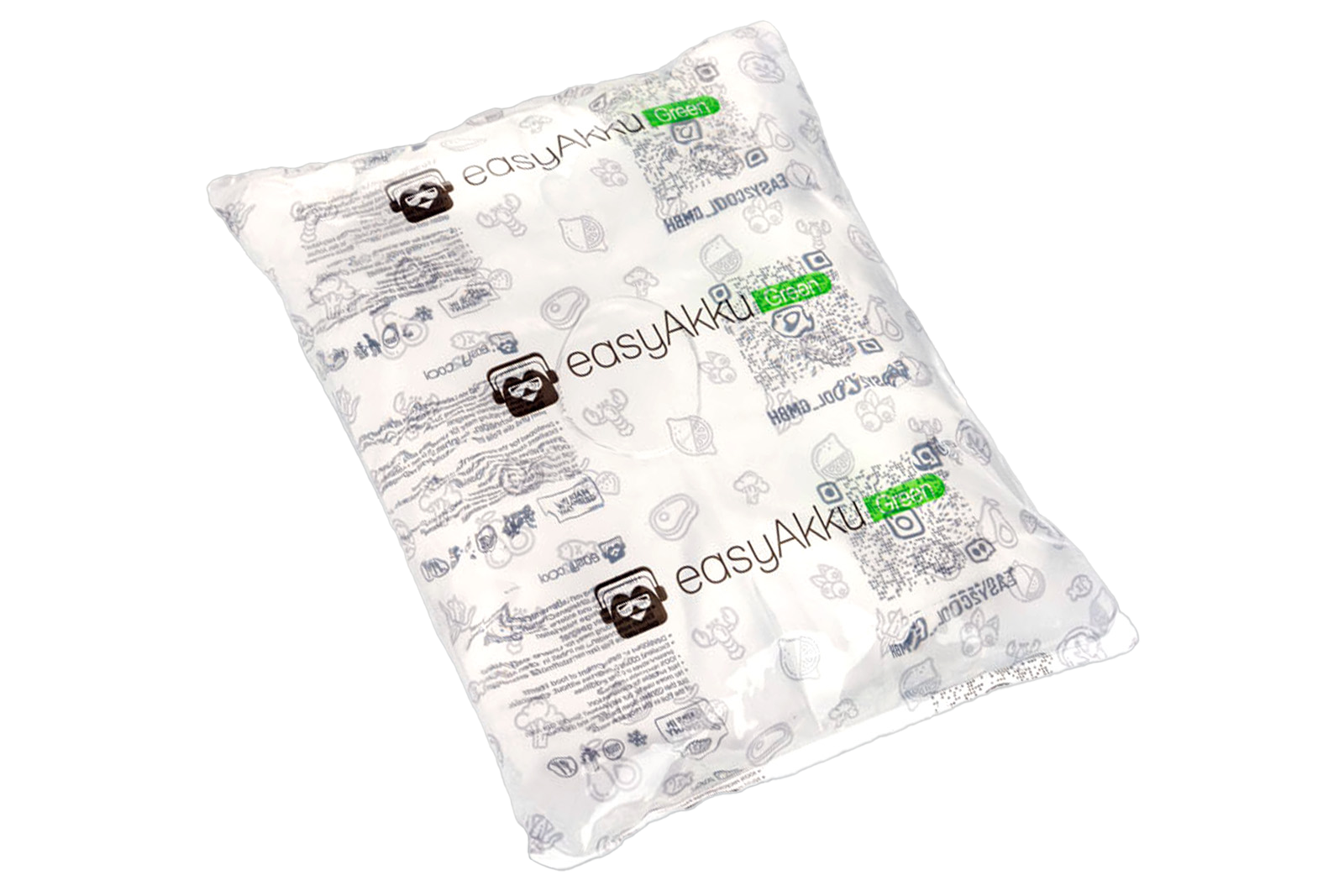

easyAkku Technology

-

The thin outer skin of the cold pack is made of a material, which is 100% recyclable

-

It has excellent cooling properties thanks to its special filling

-

The corners of easyAkku cold packs are rounded to not damage your products during transport

-

The quality of our products is confirmed in regular checks

-

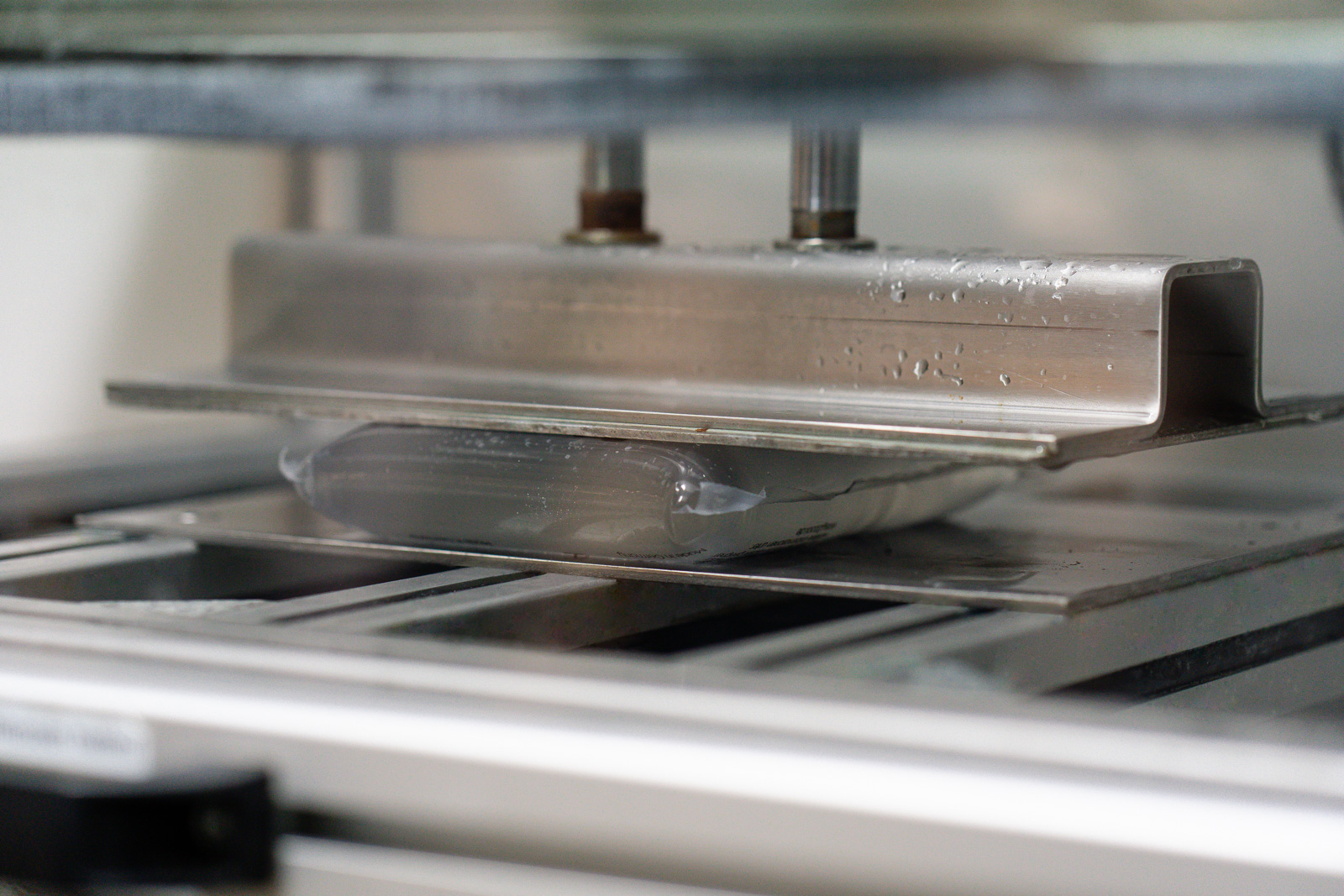

In addition to climate tests, the easyAkkus get tested in a pressure test to meet the high requirements of refrigerated shipping

-

Our high quality standards were certified in the context of the ISO 9001 & 14001 certification

Consulting & Tests